Moisture is an unavoidable factor in many packaging and usage environments. From beverage filling lines and cold-chain logistics to household bathrooms and industrial cleaning areas, bottle caps are often handled with wet hands or exposed to condensation and splashes. Under these conditions, closure safety depends heavily on thread design and surface interaction. Helicap and Streamcap are frequently discussed in this context because their structures are developed to address practical issues related to grip, sealing stability, and repeated handling when moisture is present. Understanding how Helicap threads perform in wet conditions helps users and manufacturers make more informed packaging choices.

Why Wet Conditions Increase Closure Risks

When water, oil, or other liquids are present on a cap surface, friction is reduced. This makes caps harder to tighten properly and easier to slip during opening or closing. In production environments, wet conditions may occur after rinsing bottles, during filling with chilled liquids, or when condensation forms due to temperature differences. For end users, moisture is common in kitchens, bathrooms, outdoor settings, and workplaces where gloves or wet hands are involved.

A cap that slips during tightening may not reach the intended closure position, which increases the chance of leakage during transportation or storage. During opening, a slippery cap can require additional force, increasing the risk of sudden movement that causes spills. These everyday issues explain why thread geometry and surface texture are central to closure safety.

Helicap Thread Geometry and Surface Interaction

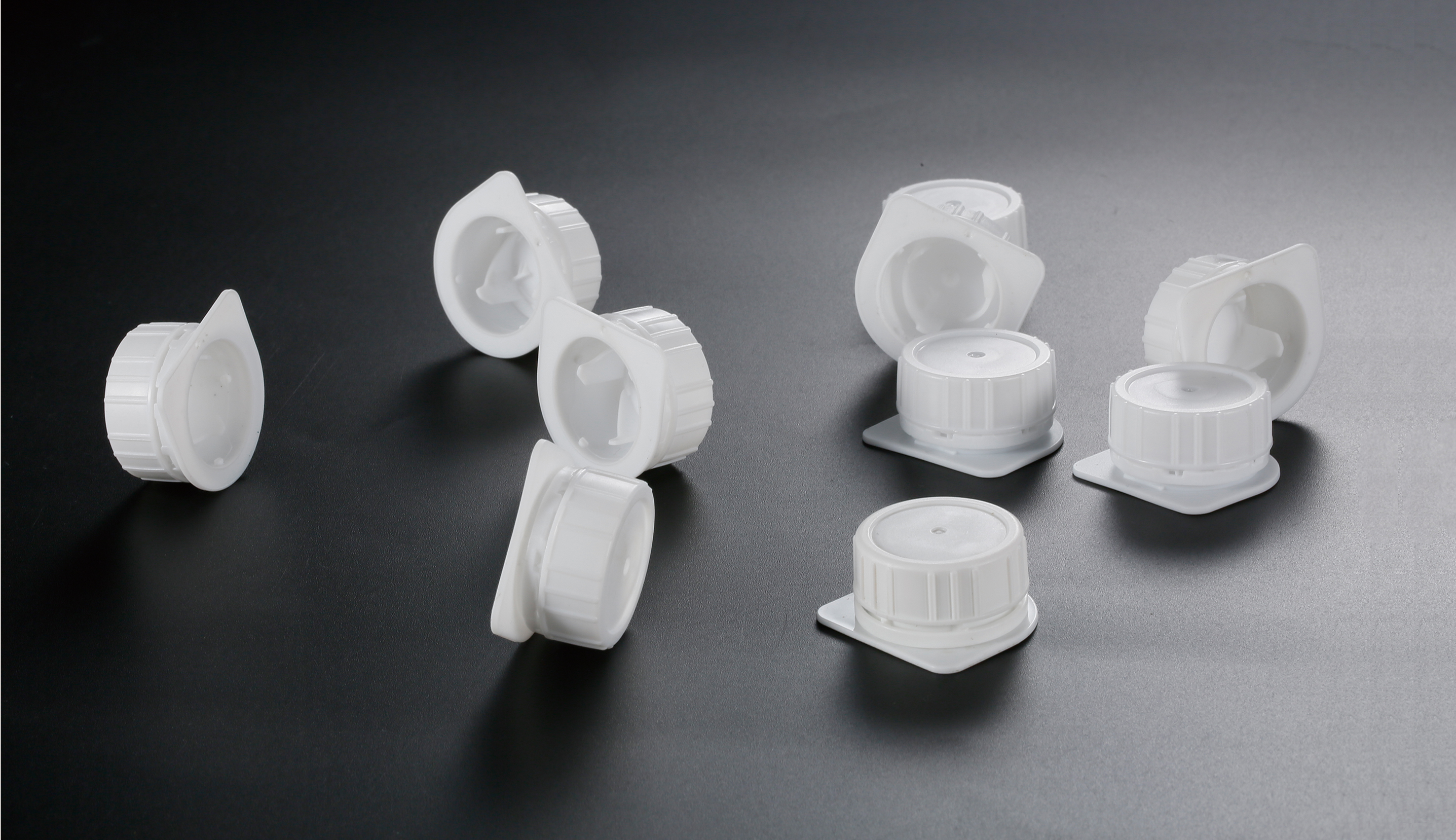

Helicap threads are designed with side anti-slip features that directly address reduced friction in wet conditions. Instead of relying solely on smooth, standard thread profiles, the thread sides are shaped to increase contact area between the cap and the bottle neck. This structure helps maintain engagement even when moisture is present on the surface.

The anti-slip thread design supports more controlled rotation during both tightening and loosening. When hands or gloves are wet, this controlled engagement helps prevent sudden slipping that can interrupt the closing process. As a result, users are more likely to achieve a consistent seal without needing excessive force, which can otherwise stress the cap or bottle threads.

Streamcap also places emphasis on smooth but secure threading. While its surface may feel less textured, the thread tolerance is designed to maintain stable engagement, reducing the likelihood of partial closure when moisture affects grip.

Grip Support During Manual Handling

Thread safety in wet conditions is closely linked to how easily users can grip and control the cap. Helicap incorporates external thread features that extend slightly beyond the cap body. These features improve hand contact and reduce reliance on dry friction alone. Even when water or residue is present, users can maintain control over the cap’s movement.

This design is particularly relevant in environments where caps are opened and closed frequently, such as shared beverage containers, refillable cleaning products, or personal care items used in showers or sinks. A cap that supports stable grip reduces the chance of dropping the container or spilling contents during handling.

Streamcap focuses on an easy opening and closing mechanism that does not require high torque. In wet conditions, lower force requirements help users maintain control, especially when dexterity is limited or gloves are worn.

Sealing Consistency Despite Moisture Exposure

Wet conditions do not only affect grip; they can also influence sealing performance. If moisture enters the thread area during closing, uneven tightening may occur. Helicap threads are designed to guide the cap into a consistent closing path, even if water is present on the bottle neck or threads.

This guidance helps ensure that the cap seats evenly against the bottle opening. An even seating reduces the chance of localized gaps that could later allow leakage. While no cap can eliminate all risks, a thread design that promotes consistent alignment plays a practical role in reducing sealing variability caused by wet surfaces.

Streamcap’s thread design similarly supports repeated resealing. When users open and close the cap multiple times in moist environments, maintaining alignment helps preserve sealing function over the product’s life cycle.

English

English  русский

русский عربى

عربى