Selecting the right closure is an important part of packaging design, especially when dealing with liquid products that require safe storage and repeated access. The Safety Closure Screw Cap for Liquid Packaging and the Multi-Use Bottle Cap are two solutions that combine protection, convenience, and functionality. These closures not only safeguard the product from contamination and leakage but also improve user experience through ease of handling and reusability. Understanding their working principles and applications helps businesses and consumers choose packaging that aligns with their practical needs.

The Protective Function of Safety Closure Screw Caps

Safety closure screw caps are designed to secure liquid contents by forming an airtight and spill-resistant seal. This type of cap often incorporates a double-lock mechanism or tamper-evident ring, providing visual assurance that the product has not been opened before purchase. For industries dealing with chemicals, cleaning agents, or pharmaceuticals, this feature adds a necessary layer of safety during transportation and consumer use.

Another critical aspect of these caps is their child-resistant function. The cap’s internal structure usually requires two coordinated motions—pressing down and twisting—to open. This mechanism prevents accidental access by children while remaining practical for adult users. The design supports compliance with various packaging safety regulations, particularly in sectors that handle potentially hazardous or ingestible liquids.

Versatility and Everyday Use of Multi-Use Bottle Caps

The Multi-Use Bottle Cap emphasizes practicality for products that are opened and closed frequently. It ensures that the bottle remains tightly sealed after each use, preserving product quality and preventing unnecessary waste. This feature is especially useful for beverages, personal care items, or household cleaning liquids that consumers use daily. By maintaining a consistent seal, multi-use caps help avoid spillage and extend the shelf life of the product.

From a usability perspective, these caps are designed for effortless operation. Threaded closures enable users to open and close bottles smoothly, without applying excessive force. Some caps also include textured grips or ergonomic shapes to enhance comfort, particularly for people with limited hand strength. The overall result is a closure that supports repeated use while maintaining performance over time.

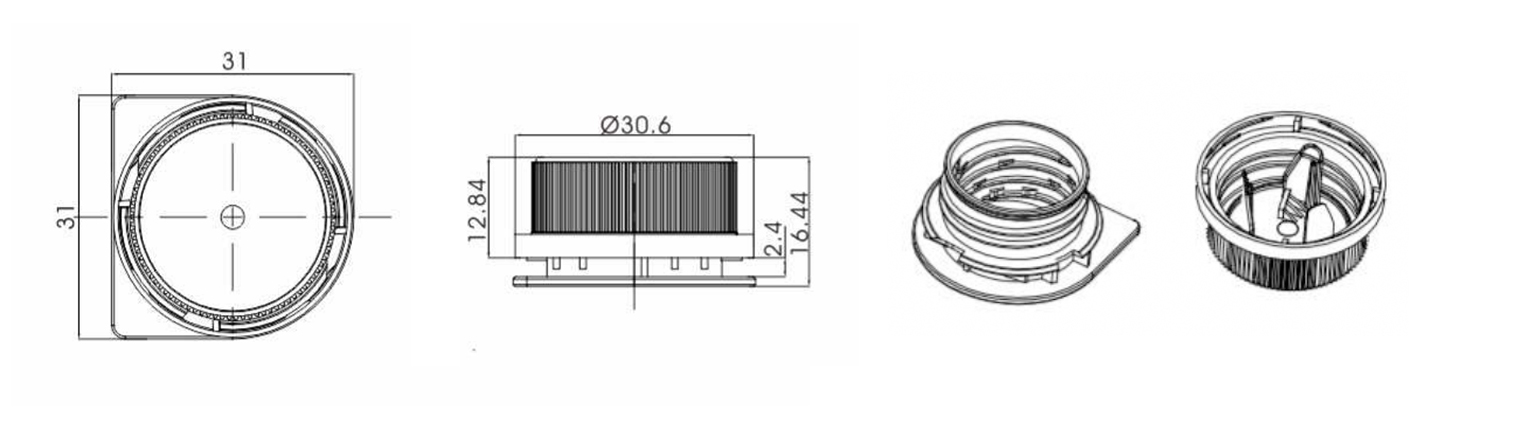

Material Selection and Engineering Precision

The durability and effectiveness of both safety closure and multi-use bottle caps depend largely on material choice. High-grade plastics such as polypropylene (PP) and polyethylene (PE) are commonly used because they offer flexibility, chemical resistance, and mechanical strength. These materials prevent deformation during use, ensuring that the cap fits precisely on the bottle neck.

Advanced injection molding techniques further improve the structural consistency of each cap. Manufacturers also take into account torque balance—the amount of force required to close or open the cap—to ensure that the product remains sealed but easy to use. These engineering details have a direct impact on how effectively the closure protects its contents and supports repeated operation.

Safety Compliance and Consumer Assurance

Safety closure screw caps are often subject to specific compliance standards that evaluate their resistance to accidental opening and leakage. These tests simulate real-life conditions, such as vibration during transport or prolonged storage, to confirm the closure’s integrity. Many liquid packaging sectors, from pharmaceuticals to household chemicals, rely on such closures to meet regulatory expectations.

For consumers, the presence of a tamper-evident band or safety ring serves as a visible indicator that the product has not been previously opened. This small but important detail builds confidence in product authenticity and handling. Moreover, the use of child-resistant mechanisms significantly reduces the risk of accidental ingestion, a concern particularly relevant to cleaning or chemical products stored in homes.

Sustainability and Reuse Opportunities

Beyond safety and convenience, sustainability has become a growing focus in packaging design. Multi-use bottle caps contribute to this trend by allowing bottles to be refilled and reused multiple times. This approach reduces single-use plastic waste and supports circular economy practices. Refillable containers paired with durable caps extend the lifespan of packaging materials, which benefits both businesses and environmentally conscious consumers.

Some producers are exploring recyclable or biodegradable polymers to make closure systems more eco-friendly. The balance between performance and sustainability continues to shape how modern bottle caps are developed, ensuring that protective packaging can coexist with responsible environmental practices.

Practical Advantages for Manufacturers and End Users

For manufacturers, using a safety closure screw cap for liquid packaging offers consistent sealing performance during automated bottling processes. Caps can be customized in size, color, or surface texture to fit branding or labeling requirements without sacrificing functionality.

English

English  русский

русский عربى

عربى