Questions about how a Plastic Packaging Bottle Cap performs with thicker liquids often arise when manufacturers or consumers compare different closure options. Similar attention is given to how a Dairy Carton Packaging Screw Cap manages flow control and product protection. Both types of caps focus on usability and functional stability, especially when liquids have higher viscosity. Understanding the structural features behind these closures helps users choose packaging that matches the characteristics of their product.

Cap Structure That Supports Controlled Dispensing

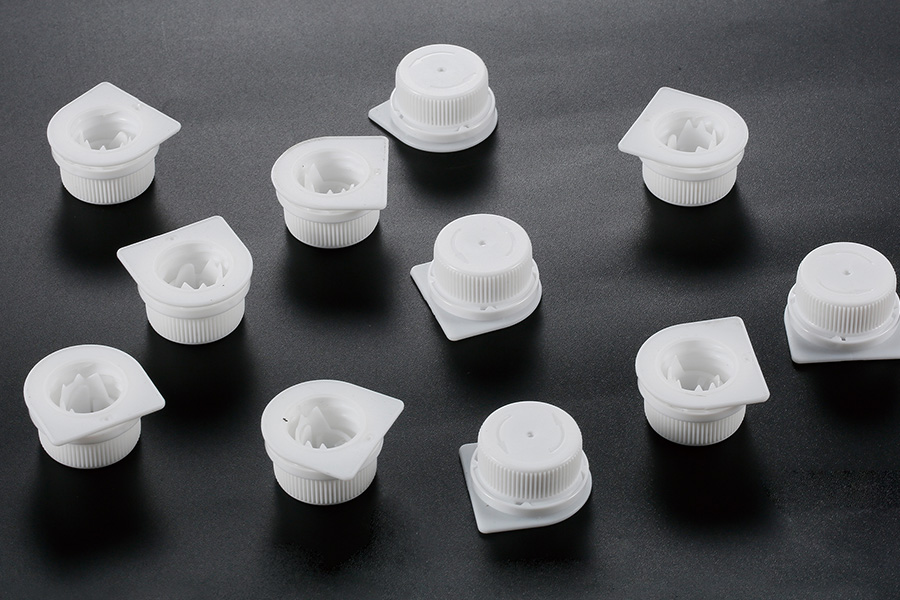

Thick liquids—such as lotions, syrups, concentrated detergents, or dairy-based formulations—require a cap that supports steady flow without sudden surges. The structure of a plastic packaging bottle cap plays a central role here. When the internal thread design pairs well with the bottle’s neck, the cap can maintain a balanced seal that limits air exchange. This helps create a smoother dispensing experience because the liquid does not rush out due to uncontrolled pressure changes inside the container.

A carefully spaced thread pattern also allows the user to open and close the cap with consistent force. This matters for dense liquids since users often need to partially open the cap to manage flow more precisely. A cap that opens easily but holds its position securely reduces the chance of accidental over-pouring, which is a common concern with thick liquids.

The same principle is applied in the dairy carton packaging screw cap. Its side anti-slip threads give users a better grip, allowing them to adjust the opening angle even when the carton surface is slightly damp. The combination of grip texture and screw design helps the cap maintain functional stability during repeated use.

Material Characteristics That Withstand Frequent Use

Dense liquids often stick to surfaces, meaning the cap tends to gather residue with repeated opening. For this reason, material selection becomes an important factor. A plastic cap made from durable resin maintains shape and structural integrity even when exposed to contents that place more pressure on the cap’s interior walls.

Thick liquids may also be packaged in environments with varying temperatures. During transportation or storage, higher ambient temperatures can make dense liquids expand slightly. A cap with stable material composition prevents deformation that might loosen the seal. Users benefit from this because a consistent seal helps protect the remaining contents from drying or contamination between uses.

For carton-based applications, the dairy carton packaging screw cap uses plastic that resists minor impacts and general pressure from stacking during distribution. This is essential for dairy products or beverages where unintentional pressure on the carton could otherwise loosen or misalign a cap.

Ease of Opening for Users with Different Strength Levels

When handling containers with thick liquids, the cap’s opening force becomes more noticeable. A cap that is difficult to twist can affect user experience, especially when hands are wet, oily, or weakened by repetitive movements. Plastic packaging bottle caps designed with ergonomic ridges and shallow grooves help users open the container without applying excessive force.

The dairy carton packaging screw cap incorporates side anti-slip threads that serve the same purpose. These threads promote better grip during twisting, even when the carton surface has condensation. This is beneficial in household environments, restaurants, food factories, or any place where users need quick, predictable bottle access.

A user-friendly opening mechanism also supports controlled dispensing. Being able to reopen the cap smoothly after each use helps maintain a consistent flow rate for thick liquids without sudden release or blockage.

Seal Performance That Protects Viscous Contents

A central concern with thick liquids is preventing leakage, especially when containers are laid horizontally or handled frequently. The sealing surface inside a plastic packaging bottle cap is designed to press evenly against the container opening. This even pressure distribution helps limit gaps that could allow slow seepage.

For users, this matters in everyday use. Thick liquids tend to accumulate around the mouth of the container, and if the cap’s seal is uneven, residue could push through small gaps. A uniform contact surface supports cleaner storage and reduces the likelihood of stains on shelves or transportation boxes.

On the dairy carton packaging screw cap, the resealable function allows users to access the contents multiple times while keeping the carton closed securely when not in use. This feature is essential for dairy-based liquids that need freshness retention and controlled exposure to air.

Fit Versatility for Different Packaging Formats

Thick liquids are found across many industries, ranging from household cleaning products to personal care, food, and industrial solutions. Because of this wide range, caps need to be adaptable to various bottle shapes and mouth diameters. Plastic packaging bottle caps are offered in multiple sizes, including larger formats that suit high-volume containers. Larger caps also allow clearer label placement or embossed branding when required.

The dairy carton packaging screw cap follows a similar flexible approach. Its structure is compatible with common carton designs while providing a stable attachment during filling and sealing processes. This compatibility helps brands maintain consistent packaging lines without major equipment changes.

English

English  русский

русский عربى

عربى