Two of the more widely adopted closure types in the food packaging sector are twist-off caps and flip-top caps. Both have established their positions in the market, but each caters to different functional needs and consumer behaviors. This article explores the design, usability, and material trends behind these closures, with special attention to the rising demand for reusable bottle tops and sealed bottle tops.

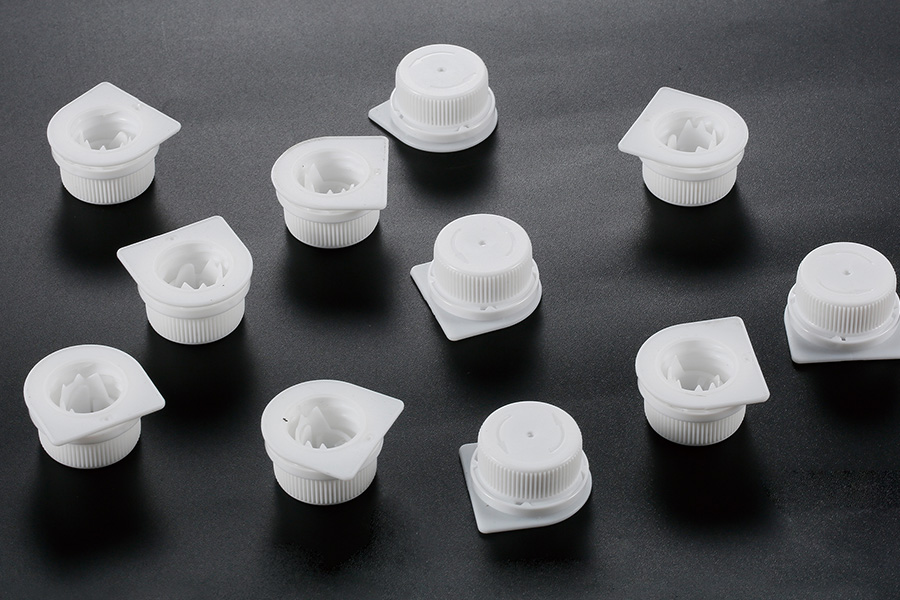

Twist-off caps are commonly found on glass jars, beverage bottles, and condiments. Their appeal lies in the simplicity of their design—requiring only a twist motion to open or close the container. This type of cap typically provides a secure, air-tight seal, making it ideal for products that require long shelf life or sterile conditions. Sealed bottle tops are often based on this mechanism, incorporating tamper-evident bands or foil layers underneath to reinforce safety. These additions not only prevent contamination but also offer visual assurance to consumers that the product has not been previously opened.

On the other hand, flip-top caps are favored for their ease of access. These caps are hinged and open with a single motion, allowing users to dispense the contents without fully removing the cap. This is particularly useful for sauces, dressings, and other liquid or semi-liquid foods. Flip-top caps support one-handed operation, making them popular in kitchens and on-the-go scenarios. Their resealable design fits well with the growing movement toward reusable bottle tops, encouraging consumers to refill containers instead of discarding them after a single use.

A significant trend shaping both cap types is the integration of reusable bottle tops into various packaging formats. With environmental regulations and consumer expectations pushing for sustainable options, manufacturers are designing caps that not only serve their initial sealing purpose but can also be reused multiple times. This requires attention to material durability, thread integrity, and hinge resistance. Whether it's a twist-off or a flip-top, the cap must maintain functionality over repeated openings and closings without degrading performance.

In terms of food safety, sealed bottle tops are evolving to provide a balance between security and user-friendliness. For instance, multi-layered sealing systems are being used more frequently—such as combining induction seals with threaded caps or snap-fit closures. These ensure that the contents remain fresh while offering an easy removal experience. Innovations in polymer science are enabling tighter seals without increasing torque requirements, benefiting both cap types.

Material selection plays an important role in cap performance and sustainability. Polypropylene and polyethylene are the more commonly used plastics in both twist-off and flip-top applications. However, recent shifts toward biodegradable and recyclable materials are influencing cap development. These changes also impact the manufacturing process, as reusable bottle tops must balance eco-friendly composition with longevity and sealing strength.

Another area where these two mechanisms diverge is in dispensing control. Flip-top caps can be paired with flow-control nozzles or valves to allow precise application of condiments or creams. This adds functional value to the user experience. Twist-off caps, while typically not associated with precision dispensing, are better suited for products that are scooped or poured in larger quantities. Regardless of the dispensing method, both closures can serve as sealed bottle tops when properly engineered.

Consumer perception is also a key driver behind packaging trends. People tend to associate twist-off caps with traditional products and home-style goods, while flip-tops suggest modernity and convenience. As reusable packaging continues to gain ground, consumers are paying closer attention to how easily a cap can be resealed or reused. This opens new opportunities for brands to position themselves around reusable bottle tops as a feature, not just a necessity.

In conclusion, both twist-off and flip-top caps continue to evolve in response to changing market demands. Their adoption often depends on the product type, desired user interaction, and branding goals. At the same time, the rising focus on sealed bottle tops and reusable bottle tops is influencing the direction of cap design across the food packaging industry. As materials and manufacturing processes improve, the future of closure systems will likely be shaped by a blend of practicality, safety, and environmental responsibility.

English

English  русский

русский عربى

عربى