A modular cap system allows manufacturers to streamline production while offering a variety of closure options suited for different products. This versatility is particularly beneficial for companies managing extensive portfolios, including personal care items such as lotions. One notable innovation within this field is the lotion-specific custom closure, which combines functionality and adaptability. Alongside this, precision-fit caps ensure secure sealing and user convenience, creating a seamless consumer experience.

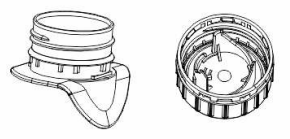

The concept of modular cap designs revolves around a standardized base with interchangeable components that can be adapted for various products. This approach reduces tooling costs and shortens advance times, allowing businesses to respond swiftly to market demands. For products like lotions, the lotion-specific custom closure is designed to accommodate the unique viscosity and dispensing requirements. Unlike generic caps, these closures are tailored to control flow, prevent leakage, and protect product integrity, making them essential components in multi-product packaging strategies.

Precision-fit caps play a crucial role in modular designs by ensuring compatibility and reliability across different container types. The close tolerances achieved during manufacturing prevent issues such as cross-threading and inconsistent torque, which can impact consumer satisfaction and product safety. By integrating precision-fit caps with lotion-specific custom closures, manufacturers can offer a robust packaging solution that meets both functional and aesthetic needs. This combination supports efficient assembly and consistent performance across diverse product lines.

One of the primary advantages of modular cap designs for multi-product lines is their ability to simplify inventory management. Companies can stock a limited range of cap components that serve multiple products, reducing warehousing costs and waste. The lotion-specific custom closure fits seamlessly into this system by catering to the specific needs of lotion products without requiring a completely different cap design. This modularity extends to precision-fit caps, which can be engineered to fit various container neck finishes, further enhancing the adaptability of the packaging line.

Customization is another key benefit of modular cap systems. Manufacturers can modify features such as dispensing mechanisms, tamper-evident elements, and sealing options without redesigning the entire cap. The lotion-specific custom closure exemplifies this flexibility by incorporating specialized inserts or valves suited for lotion dispensing. Similarly, precision-fit caps can be produced in various materials, colors, and textures, allowing brands to maintain their visual identity while benefiting from standardized components. This adaptability helps companies respond to consumer preferences and regulatory requirements effectively.

In addition to operational benefits, modular cap designs contribute to sustainability efforts. By using interchangeable components like precision-fit caps and lotion-specific custom closures, manufacturers can optimize material usage and reduce environmental impact. For example, selecting recyclable plastics and less excess packaging aligns with growing consumer demand for eco-conscious products. Moreover, the modular approach supports easier repair and replacement, extending the life cycle of packaging components and reducing waste.

The integration of lotion-specific custom closures within modular cap designs also improves the end-user experience. These closures provide controlled dispensing, which is crucial for lotions to prevent overuse or spillage. Combined with precision-fit caps that ensure a secure seal, consumers benefit from packaging that maintains product freshness and prevents contamination. This attention to detail reinforces brand trust and encourages repeat purchases.

From a manufacturing perspective, modular cap designs simplify production lines by enabling rapid changeovers between product types. Precision-fit caps reduce assembly errors and downtime, while lotion-specific custom closures lessen the need for specialized equipment. This efficiency translates to cost savings and increased flexibility, allowing companies to introduce new products or adjust existing ones without significant investment. As a result, modular designs help businesses remain competitive in dynamic markets.

In conclusion, modular cap designs offer a versatile and efficient solution for companies managing multiple product lines. The lotion-specific custom closure plays a vital role in addressing the unique needs of lotion packaging, while precision-fit caps ensure reliable performance across various containers. Together, they provide a packaging system that balances customization, operational efficiency, and user satisfaction. By adopting modular cap designs, manufacturers can optimize inventory, reduce costs, support sustainability, and enhance consumer experience, making it a valuable approach in today’s packaging landscape.

English

English  русский

русский عربى

عربى