Packaging solutions are becoming increasingly important in everyday life, especially when it comes to items people use frequently. A multi-use bottle cap plays a significant role in extending the usefulness of products ranging from beverages to household cleaners, while the plastic packaging bottle cap continues to evolve with features that focus on practicality and convenience. Modern designs are aimed at making these caps easier to handle while maintaining durability and functionality for repeated use.

Reusability That Adds Practical Valu

A defining feature of multi-use bottle caps is their ability to withstand repeated opening and closing without compromising the seal. This function supports products that are accessed multiple times during their lifecycle, such as water bottles, lotions, or detergents. The reusability reduces unnecessary packaging waste and ensures that consumers can rely on a consistent closure every time the cap is used. This design focus not only helps maintain product freshness but also improves the overall handling experience.

Thoughtful Opening and Closing Mechanisms

Ease of use is central to how plastic packaging bottle caps are designed. Many caps incorporate simple mechanisms that allow them to be opened with minimal effort. This is especially important for individuals who may have limited grip strength or dexterity. By creating caps that do not require excessive force, manufacturers make everyday tasks like pouring, drinking, or dispensing far more accessible. Whether on a desk, in the kitchen, or outdoors, these features ensure the cap provides smooth functionality in different settings.

Different Sizes for Different Applications

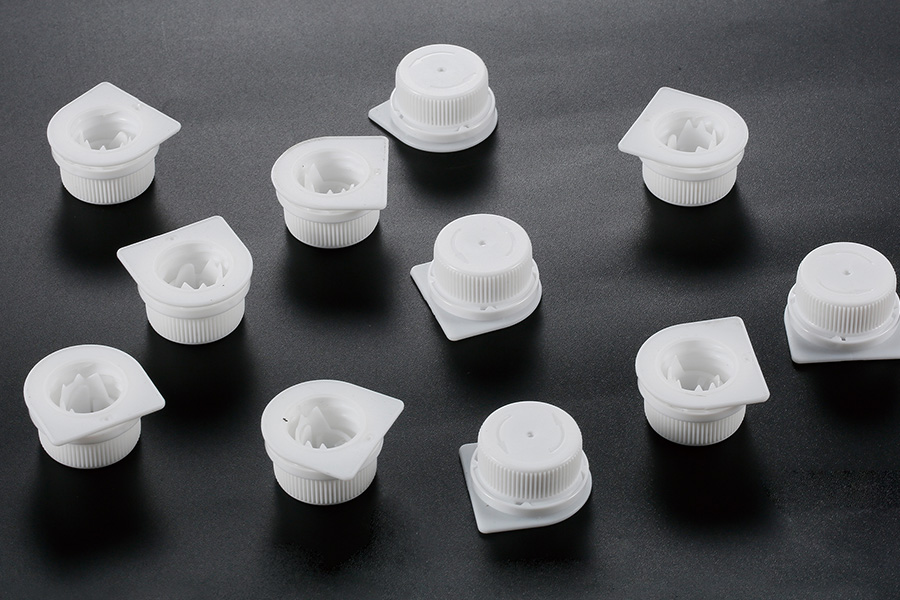

Bottle sizes vary greatly depending on the product, and the versatility of multi-use caps ensures they meet this range of needs. Larger caps are often used for bottles containing higher volumes, such as bulk cleaning supplies or family-size beverage containers. The larger surface area not only makes them easier to handle but also offers space for labeling and branding. Smaller caps, on the other hand, suit portable products where convenience and compact design are valued. This flexibility in size and design is what makes these caps adaptable across industries.

Durable Materials for Demanding Uses

Durability is another essential aspect of cap design. Plastic packaging bottle caps are manufactured from sturdy materials that resist cracking, warping, and leaks. Their resistance to environmental factors like temperature changes or exposure to moisture ensures that they continue to perform under varied conditions. For industries dealing with chemicals, cosmetics, or food, this durability helps safeguard both the product and the end user. A well-constructed cap prevents spills during storage, shipping, and daily use, which is crucial for maintaining product integrity.

Supporting Sustainability Goals

Reusable caps naturally contribute to more sustainable packaging practices.The materials chosen for production often take into account recyclability and longer lifespans, aligning with wider eco-friendly packaging initiatives. For consumers and businesses alike, this offers a practical step toward lowering environmental impact without compromising everyday functionality.

Balancing Function and User Experience

At the core of multi-use bottle cap design is the balance between technical performance and user comfort. A secure seal, ease of operation, adaptable sizing, and strong materials all contribute to making the cap an effective packaging component. At the same time, these features directly improve the handling experience for users who interact with the product daily. This approach ensures that the cap not only protects what is inside but also supports convenient and efficient use in varied scenarios.

English

English  русский

русский عربى

عربى