Customized bottle caps are no longer just simple closures; they have transformed into sophisticated components that enhance the overall user experience. Whether used in beverage, food, cosmetic, or pharmaceutical packaging, these caps are designed to align with product types, container shapes, and brand identities. The ability to tailor every aspect—from size and shape to color and opening mechanisms—enables manufacturers to address specific challenges such as leakage prevention, ease of use, and product freshness.

The carton spout cap exemplifies the impact of customization on packaging innovation. Traditionally, cartons relied on standard openings that lacked versatility and ease of use. The introduction of carton spout caps has revolutionized this aspect by providing a user-friendly opening and resealing system that maintains product integrity. Customization of these caps allows manufacturers to adapt the design to different carton sizes and product viscosities, ensuring efficient pouring and small spillage.

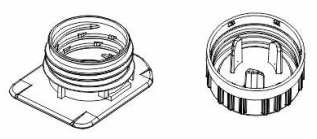

From a manufacturing perspective, customized bottle caps demand advanced production techniques and flexible tooling. Injection molding and precision engineering play significant roles in producing caps that meet tight tolerances and consistent quality standards. Manufacturers investing in these capabilities can efficiently produce a wide range of carton spout caps that satisfy the specifications of their clients, thereby strengthening their market position.

Another aspect where customization proves valuable is in branding and marketing. Customized bottle caps provide an additional canvas for brands to communicate their identity through color schemes, logos, and textures. This visual differentiation helps products stand out on crowded shelves and fosters consumer recognition and loyalty. For carton spout caps, the option to integrate distinct colors and tactile features enhances the packaging’s appeal and usability.

Sustainability concerns also drive customization in cap manufacturing. As regulations and consumer expectations evolve, there is increasing demand for eco-friendly materials and designs. Customized bottle caps made from recyclable or biodegradable plastics demonstrate a commitment to environmental responsibility. Customization in this context means balancing functional performance with sustainable material choices without compromising product safety.

Customization enables manufacturers to respond quickly to market trends and emerging consumer needs. For example, the rise of on-the-go beverages has prompted the development of carton spout caps with spill-resistant features and ergonomic designs. Manufacturers that can customize their caps to incorporate such features gain a competitive edge by providing solutions that enhance convenience and portability.

Moreover, customized bottle caps improve supply chain efficiency by allowing for standardized components adapted to specific applications. Carton spout caps designed with modular elements can fit multiple carton designs, reducing the complexity and cost of inventory management. This flexibility benefits both manufacturers and clients by streamlining production and reducing advance times.

In the context of product safety and regulatory compliance, customization offers a pathway to meet strict standards. Customized bottle caps can incorporate tamper-evident features and child-resistant mechanisms that align with safety requirements. For carton spout caps, precise engineering ensures reliable sealing and prevents contamination, protecting both the product and the consumer.

The integration of digital technologies into cap manufacturing further enhances customization capabilities. Advanced design software and 3D prototyping allow manufacturers to create and test customized bottle caps and carton spout caps rapidly. This accelerates development cycles and enables precise adjustments based on client feedback, improving the final product’s performance.

In conclusion, customization serves as a crucial competitive advantage in cap manufacturing. Customized bottle caps and carton spout caps exemplify how tailored solutions can address functional, aesthetic, sustainability, and regulatory demands. Manufacturers embracing customization are better positioned to innovate and satisfy diverse market needs, ultimately fostering stronger partnerships with clients and delivering packaging solutions that resonate with consumers. The ability to customize at every stage—from design to production—continues to shape the future of cap manufacturing.

English

English  русский

русский عربى

عربى