Choosing the right plastic resin for food-grade closures is a critical aspect of packaging design, especially for products such as juice carton caps and tamper-evident caps. The selection process influences not only the safety and durability of the closure but also its functionality, environmental impact, and compatibility with the packaged product. In the beverage industry, where juice carton caps are commonly used, the importance of choosing appropriate materials cannot be overstated. This article explores the key factors and considerations involved in selecting plastic resins for food-grade closures, focusing on juice carton caps and tamper-evident caps.

Food-grade closures must comply with stringent safety standards to ensure that they do not contaminate the product or degrade over time. The plastic resin used for manufacturing juice carton caps plays a pivotal role in maintaining the integrity and quality of the beverage inside. Polypropylene (PP) and high-density polyethylene (HDPE) are among the widely used plastic resins due to their chemical resistance, ease of molding, and compliance with food safety regulations. Both resins offer sufficient durability to withstand transportation and consumer handling while maintaining an effective seal.

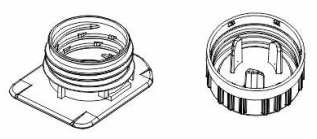

Tamper-evident caps add an additional layer of security and consumer confidence by providing a visual indication if the product has been opened. The resin choice for tamper-evident caps must balance rigidity with flexibility, allowing the tamper-evident feature to function properly without compromising the cap’s overall strength. Resins like polypropylene offer reliable dimensional stability, which is essential for the precise manufacturing of tamper-evident bands or seals that break away as intended upon opening.

Beyond chemical compatibility and mechanical properties, environmental considerations are increasingly influencing resin selection for juice carton caps and tamper-evident caps. Manufacturers are exploring recyclable and sustainably sourced materials to reduce the environmental footprint of packaging components. Selecting resins that can be recycled in existing waste management systems supports circular economy goals while meeting regulatory requirements for sustainability.

The molding process also affects resin choice. Injection molding is the standard manufacturing method for producing juice carton caps and tamper-evident caps. The resin must have good flow characteristics to fill intricate molds and produce consistent, defect-free parts. Polypropylene’s versatility in injection molding makes it a preferred choice, allowing for precise control over cap dimensions and features like threading and sealing surfaces.

Thermal resistance is another important factor in resin selection. Juice carton caps often undergo hot-filling or pasteurization processes, where the closure must withstand elevated temperatures without warping or losing its sealing properties. Resins with suitable heat resistance, such as polypropylene, help maintain the cap’s shape and ensure a reliable seal throughout the product’s shelf life.

Barrier properties are sometimes a consideration, especially when the beverage is sensitive to oxygen or moisture. While the cap alone does not provide the primary barrier, the resin must not degrade or allow contamination that could affect the beverage quality. In some designs, additional sealing films or liners complement the resin properties to enhance the overall barrier performance.

When selecting plastic resin for tamper-evident caps, attention must also be given to the cap’s interaction with the container neck finish. The resin’s mechanical properties influence the torque needed to open the cap and the ease with which tamper-evident features function. Properly selected resin ensures the cap seals tightly to prevent leakage, yet remains user-friendly when opening.

Compatibility with food-grade adhesives or sealing liners is also important. Some juice carton caps require additional sealing elements made from materials such as aluminum foil or polymer films. The resin must bond well or maintain close contact with these elements to preserve the packaging’s overall integrity.

Cost considerations often influence resin choice, but they must be balanced with performance requirements and regulatory compliance. Choosing a resin solely based on price could risk the safety or functionality of juice carton caps and tamper-evident caps. A thorough evaluation of resin properties ensures a balance between affordability and quality.

In summary, selecting the right plastic resin for food-grade closures like juice carton caps and tamper-evident caps involves evaluating multiple factors. These include safety and regulatory compliance, chemical and thermal resistance, mechanical properties, environmental impact, molding characteristics, and compatibility with other packaging components. Attention to these details ensures that the closures perform effectively, maintain product quality, and meet consumer expectations. As packaging needs evolve, ongoing research and development in resin technologies will continue to influence the design and production of food-grade closures, enhancing their role in the safe and sustainable packaging of beverages.

English

English  русский

русский عربى

عربى