Caps solutions for aseptic juice and dairy products play a crucial role in ensuring product safety, maintaining freshness, and enhancing consumer convenience. As the demand for aseptic packaging grows in the beverage industry, manufacturers and packaging designers continuously seek closure systems that meet the specific needs of these sensitive products. Among the popular options, twist-off caps and push-pull caps have gained attention for their functional advantages and suitability in aseptic juice and dairy packaging.

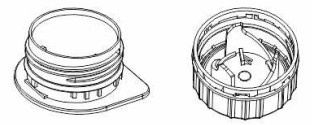

Aseptic packaging requires closures that provide a reliable barrier against contamination while preserving the product's nutritional quality. Twist-off caps have been widely adopted due to their secure sealing capabilities. These caps utilize threaded designs that allow consumers to twist the cap to open or close the container easily. Their sealing performance helps protect aseptic juices and dairy products from exposure to air and microbes, thereby extending shelf life without the need for refrigeration in many cases. The twist-off cap’s reclosability is also a significant benefit, as it allows consumers to use the product over multiple servings while maintaining freshness.

Push-pull caps offer a different functional approach tailored to convenience and controlled dispensing. These caps enable users to pull the spout open for drinking or pouring and push it back to close, providing an intuitive experience without needing to remove the entire cap. This mechanism less spillage and exposure to contaminants, which is especially valuable for aseptic juice and dairy products where maintaining hygiene is critical. Push-pull caps also cater to on-the-go consumers who require quick access and easy resealing of their beverages.

Both twist-off caps and push-pull caps are designed with materials that comply with food safety regulations, ensuring no harmful substances migrate into the liquid contents. The choice between the two depends largely on the target consumer’s preferences and product application. For instance, twist-off caps are often preferred in products where a tight seal and reusability are priorities, such as larger juice bottles or dairy containers meant for household use. Push-pull caps, meanwhile, are commonly found on single-serve or portable packaging formats, providing quick and hygienic access.

The manufacturing process for twist-off caps involves precision threading to ensure consistent fit and sealing effectiveness. This manufacturing accuracy is critical for aseptic products, where any leakage could compromise the entire batch. Likewise, push-pull caps require careful design and testing to achieve smooth operation and a secure closure when pushed back down. Both types benefit from advances in injection molding technology, which allows for custom shapes, sizes, and functionalities to fit diverse container neck finishes.

Sustainability considerations also influence cap design choices for aseptic juice and dairy products. While both twist-off caps and push-pull caps are predominantly made from recyclable plastics, some manufacturers are exploring bio-based materials and lightweight designs to reduce environmental impact. Efficient use of materials without compromising barrier properties or functionality aligns with growing consumer interest in eco-friendly packaging.

In the market, consumer education plays a role in the acceptance of twist-off caps and push-pull caps for aseptic products. Clear labeling and user instructions enhance the user experience by guiding proper opening and closing techniques, which is particularly important for push-pull caps that may be unfamiliar to some users. Packaging designers often incorporate tactile features and ergonomic shapes to facilitate grip and handling for all age groups.

From a logistics perspective, the robustness of twist-off caps and push-pull caps aids in transportation and storage by preventing leakage and maintaining product integrity under various conditions. This reliability reduces waste and ensures products reach consumers in good condition, reinforcing brand trust without reliance on refrigeration during distribution.

In summary, twist-off caps and push-pull caps provide effective closure solutions tailored to the specific challenges of aseptic juice and dairy packaging. Their functional designs offer benefits in sealing, convenience, hygiene, and consumer usability, supporting the quality and safety of aseptic products throughout their shelf life. As packaging technologies evolve, these cap types continue to adapt, reflecting the dynamic needs of the beverage industry and its consumers.

English

English  русский

русский عربى

عربى