Carton bottles serve as a staple packaging solution across beverages, household goods and personal care sectors, with their performance closely linked to the compatibility of closures. Helicap and Dreamcap, two plastic closure options designed for carton bottles, require careful matching with bottle specifications to achieve basic sealing and usability. Understanding the factors that determine their compatibility helps streamline packaging processes and avoid issues like leakage or application difficulties. This article breaks down key considerations for pairing these closures with carton bottles, offering actionable insights for packaging selection.

Bottle Neck Dimensions: The Foundation of Compatibility

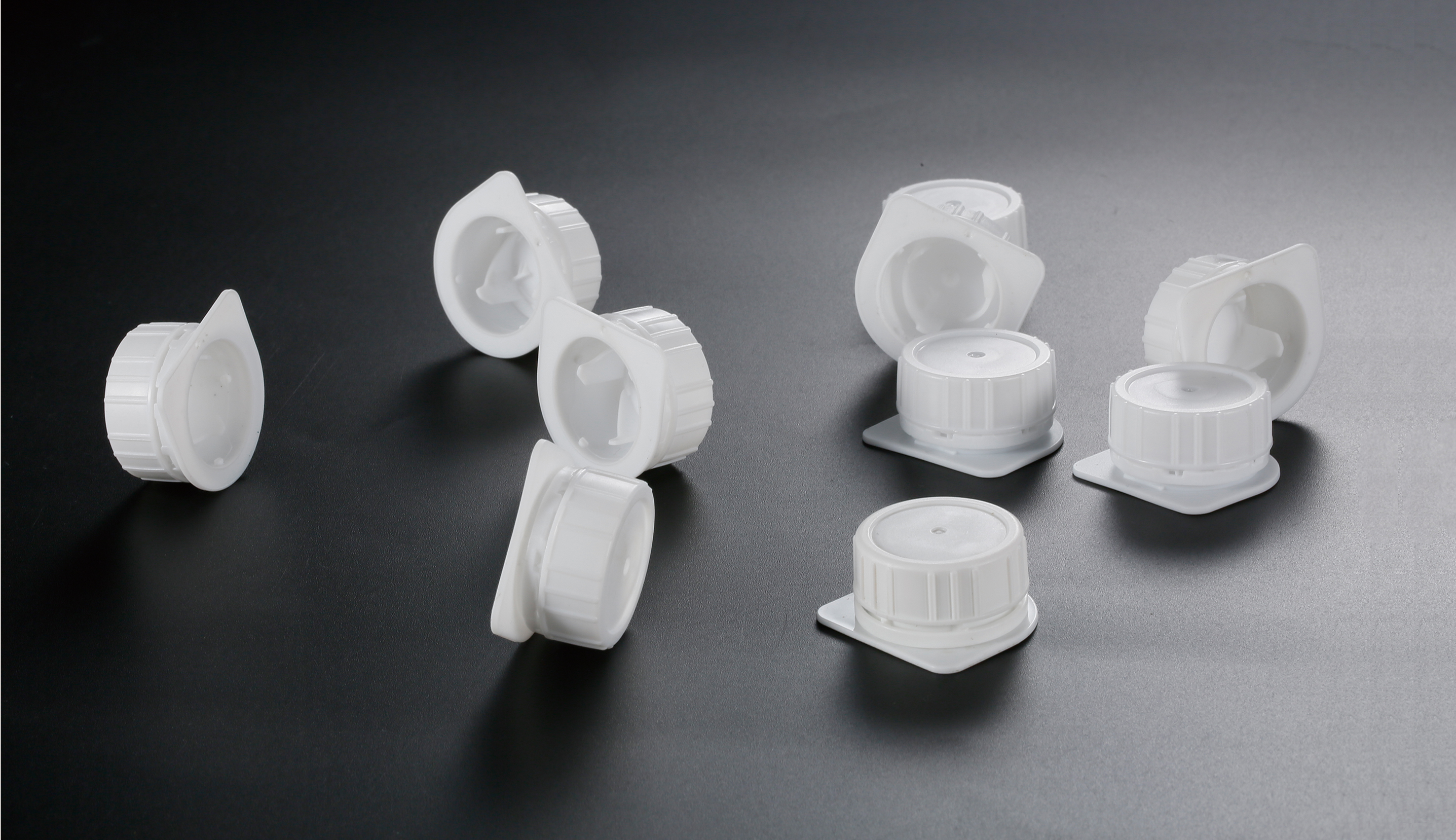

The primary factor determining whether a carton bottle works with Helicap closures lies in neck dimensions, which need to align with the closure's inner structure. Carton bottles typically feature standardized neck openings, and both Helicap and Dreamcap are manufactured to fit common size ranges, though slight variations exist based on design intent. For spiral-type Helicap, the bottle neck must have matching thread specifications—including thread pitch, depth and number of turns. Mismatched threads result in loose fitting or inability to seal, while overly tight threads may cause damage to either the closure or the bottle neck during application.

Dreamcap, designed with a snap-on structure, relies on precise neck diameter matching. The bottle neck's outer diameter should correspond to the closure's inner diameter to create a snug fit without excessive force. Many carton bottles for beverages and liquid household products adopt neck diameters between 28mm and 50mm, a range that covers the standard sizes of both Helicap and Dreamcap. It is recommended to check the closure's technical specifications for exact diameter and thread requirements before selecting carton bottles, as non-standard neck designs may require custom closures. Additionally, the neck's flatness and smoothness matter—any burrs or uneven surfaces can affect the seal integrity of both closures.

Material Compatibility: Avoiding Chemical Reactions and Deformation

Carton bottle materials, particularly the neck portion, influence the long-term performance of Helicap and Dreamcap. Many carton bottles feature a plastic or aluminum foil liner at the neck to enhance sealing, and the closure's material must be compatible with this liner to prevent adverse reactions. Helicap and Dreamcap are crafted from high-quality plastic, commonly polypropylene (PP) or polyethylene (PE), which exhibit good compatibility with many carton bottle liners. However, for bottles containing corrosive substances—such as certain household cleaners or personal care products with high alcohol content—additional checks are necessary.

PP-based Helicap and Dreamcap offer better chemical resistance, making them suitable for pairing with carton bottles holding mild corrosives, while PE variants provide more flexibility for bottles requiring frequent opening and closing. Carton bottles with paper-based necks reinforced by plastic coatings also work with these closures, as the plastic coating creates a stable surface for sealing. It is important to note that extreme temperature changes may cause material expansion or contraction; both closures and carton bottles should maintain structural stability within the product's storage and transportation temperature range to avoid seal failure.

Product Characteristics and Closure Adaptability

The nature of the product inside the carton bottle plays a role in determining suitable pairings with Helicap and Dreamcap. For liquid products prone to leakage or volatilization—such as beverages, perfumes or cleaning solutions—both closures support basic sealing needs through their structural designs. Helicap's spiral structure provides gradual compression during application, which helps accommodate slight variations in bottle neck dimensions, while Dreamcap's snap-on design offers quick sealing for high-volume production lines.

For thick or semi-liquid products, such as lotions or sauces, the closure's opening size should align with the product's flow characteristics. While Helicap and Dreamcap do not inherently restrict product viscosity, carton bottles with wider necks may require larger-sized closures to facilitate product dispensing. Additionally, products sensitive to moisture or air—such as powdered cosmetics or vitamin supplements—benefit from the secondary sealing provided by the liners in both closures, though the carton bottle's inner barrier layer also contributes to overall protection. It is advisable to test closure performance with the actual product, as prolonged contact may alter the closure's flexibility or sealing ability.

Production and Transportation Considerations

Carton bottles used in mass production need to pair with closures that support efficient application, and both Helicap and Dreamcap are designed for ease of use. However, the bottle's neck design should accommodate automated capping equipment. For example, carton bottles with tapered necks may simplify alignment with Helicap during spiral capping, while bottles with straight necks work well with Dreamcap's snap-on mechanism. Bottles with excessive neck thickness may increase capping force requirements, affecting production speed.

English

English  русский

русский عربى

عربى