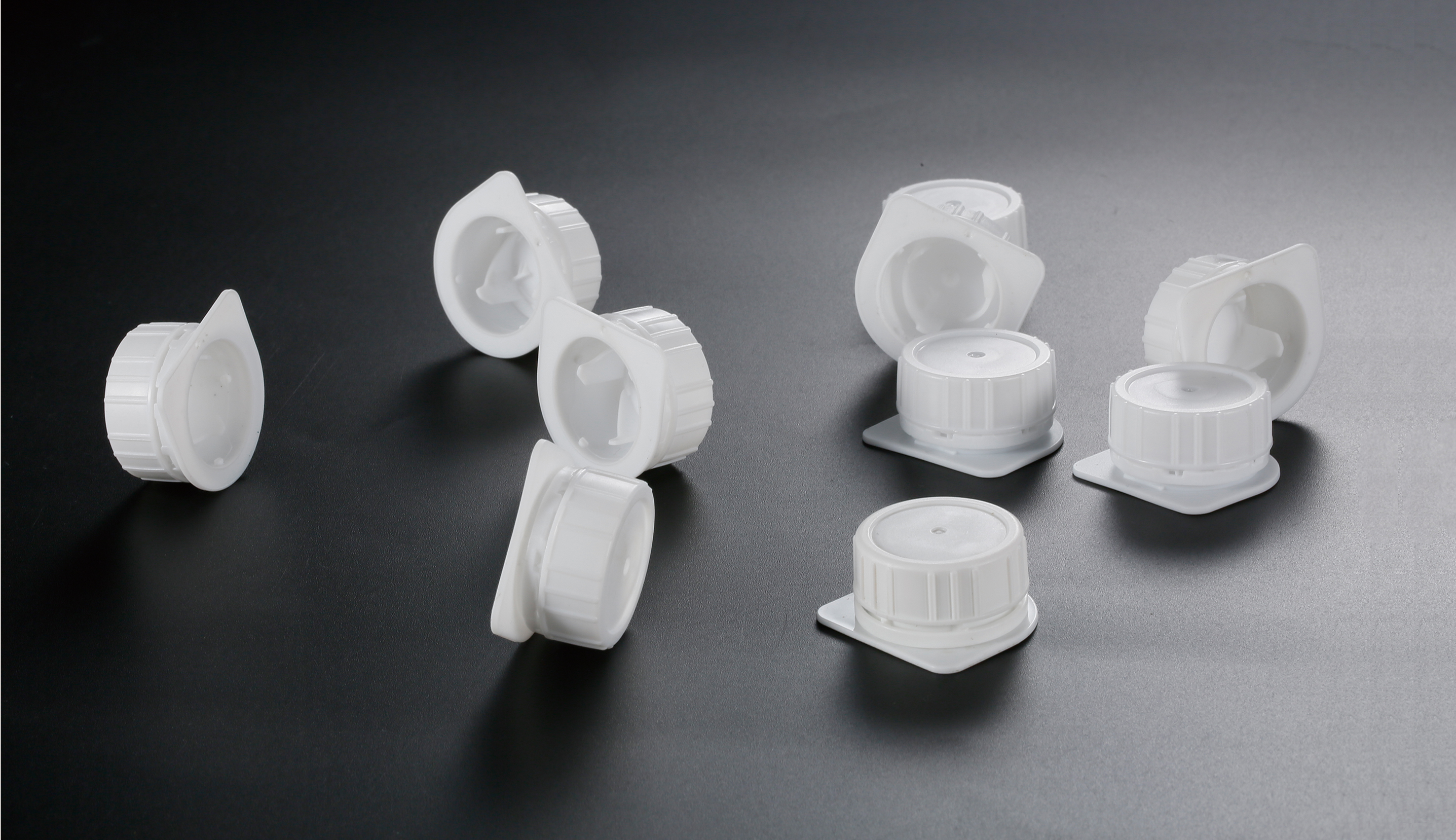

High Quality Sealed Carton Bottle Cap

-

Plastic Packaging Bottle StreamcapStreamcap plastic packaging bottle caps are designed with convenience, durability, and functionality in mind. These caps offer an good solution for sealing various types of plastic bottles, ensuring product safety and ease of use for consumers. Reliable and Reusable Design One of the key features of Streamcap plastic b...

-

Carton Bottle DreamcapThe Carton Bottle Dreamcap is an advanced plastic bottle cap designed for a wide range of packaging applications. It is primarily used for sealing carton bottle containers, ensuring a reliable, airtight seal that protects the product inside. Special Sealing Performance One of the protrude features of the Carton Bottle ...

-

Carton Packaging HelicapThe Carton Packaging Helicap is a High quality plastic bottle cap designed for secure closure, ease of use, and long-lasting performance. Whether used for beverages, household products, or personal care items, this cap provides a reliable and efficient solution for packaging needs. Reliable and Secure Seal One of the p...

Multi-Use Bottle Cap Industry Knowledge Extension

Carton Bottle Packaging Cap

The Carton Bottle Packaging Cap is designed to integrate seamlessly with carton-based containers used for liquid packaging, such as dairy products, juice, plant-based beverages, and liquid foods. This cap structure provides a functional transition between flexible carton material and a rigid, easy-to-open bottle-style interface. It typically features a wide-mouth or narrow-neck spout, depending on the viscosity of the packaged product.

One of the core design considerations of this cap is its compatibility with both high-speed assembly lines and manual filling operations. The cap can be applied via ultrasonic welding or heat sealing to ensure proper adhesion to the carton laminate. Its surface geometry is structured to support controlled pouring and reduce product spillage. Many designs in this category also include a tamper-evident ring that separates upon opening, giving consumers visual assurance of product integrity.

The cap's ergonomic contour supports both left- and right-handed users, making it accessible across various demographics. It can be manufactured using food-contact grade polypropylene or other recyclable polymers, aligning with evolving environmental standards. In certain variations, the cap is paired with tethered components to help reduce loose cap disposal and improve recyclability.

Sealed Carton Bottle Cap

The Sealed Carton Bottle Cap is specifically engineered to provide enhanced product protection through a dual-layer sealing approach. In more configurations, this cap includes both an external closure and an internal foil seal. The foil layer is either pre-applied or integrated into the closure system, forming a barrier against oxygen, moisture, and external contaminants. This makes it suitable for shelf-stable drinks, medical liquids, and sensitive nutrition-based formulas.

This cap type often features a single-twist or push-pull opening system, designed to break the internal seal during a one use. Some models incorporate a cutting blade or piercer that activates upon rotation, automatically opening the sealed membrane without needing additional tools. This feature allows consumers to access the product in one fluid motion, improving the usability of sealed liquid packaging.

The external cap is constructed for reclosure and supports repeated access without compromising the overall seal performance. The torque profile is calibrated to be firm enough to prevent accidental opening while remaining comfortable for routine use. In industrial filling environments, the Sealed Carton Bottle Cap supports aseptic processing by maintaining a closed-system environment until the product reaches the end user.

It also allows for branding or instructional elements on the top surface, including embossing or printing, without affecting performance. For environmentally conscious brands, this cap can be produced in monomaterial versions to facilitate post-use recycling without separation of components.

Multi-Use Bottle Cap

The Multi-Use Bottle Cap is built for versatility, with features that allow it to perform reliably over repeated opening and closing cycles. It is commonly used in products that require resealing, such as family-size juices, cooking liquids, and refrigerated beverages. The cap is often designed with a screw-on or snap-fit mechanism, enabling tight closure to protect freshness between uses.

To support its multi-use function, this cap typically includes an integrated sealing ring or gasket that compresses upon closure, preventing leaks and maintaining internal pressure balance. The opening design can be either a classic twist-off style or an ergonomic flip-top, depending on the user's preference and product application. Some variations may incorporate dosing or dispensing features, particularly for semi-viscous liquids such as sauces or flavored concentrates.

Material selection is key in this cap’s performance, as it must retain structural integrity through dozens of cycles. Polypropylene and HDPE are commonly used due to their durability and resistance to deformation. For convenience, some Multi-Use Bottle Cap models are equipped with a locking mechanism or audible click feedback that signals a secure closure.

This cap is also adaptable for integration into carton-based bottles, PET containers, and flexible pouches with rigid spouts, making it a versatile choice across packaging systems. For industrial applications, the cap's thread design and sealing compatibility are engineered to reduce torque variance during capping, ensuring consistent application on the filling line.

English

English  русский

русский عربى

عربى