The Helicap was developed to enhance usability in situations where traditional closures may fall short. Designed with a spiral or helical thread structure, it allows for smooth opening and re-sealing with little effort. Unlike conventional closures that may require a strong grip or two-handed operation, the Helicap was engineered for simplicity and efficiency. It has become a favored choice in markets prioritizing ease of access, such as children’s beverages, dairy drinks, and single-serve nutritional liquids.

One of the key materials used in producing the Helicap is polypropylene, a thermoplastic polymer known for its chemical resistance, lightweight nature, and compatibility with food-contact safety standards. Specifically, polypropylene bottle caps offer a balance between rigidity and flexibility, allowing them to withstand pressure changes without compromising the seal. In the context of Helicap, this material contributes to a closure that is both durable and user-friendly.

As packaging moved toward more sustainable and consumer-centered designs, the Helicap evolved in both structure and material formulation. The demand for polypropylene bottle caps increased due to their recyclability and resistance to stress cracking. These attributes made them well-suited for use in juice cartons, milk packaging, and other liquid applications where hygiene and seal integrity are essential. In many product lines, the Helicap was adopted to replace older cap models that lacked consistent sealing or ease of use.

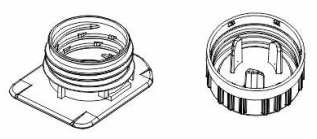

Another important element in the Helicap’s evolution is its integration with the screw cap mechanism. The helical threads on the inner surface of the Helicap closely resemble the design principles found in screw caps, which are widely used across industries. The primary distinction lies in the thread geometry and torque balance. While a typical screw cap relies on multiple rotations to achieve a tight seal, the Helicap often requires only a partial twist, providing a quicker and more ergonomic solution. This hybrid approach allows manufacturers to preserve the sealing performance of a screw cap while improving the consumer interaction.

In modern production lines, the manufacturing process of polypropylene bottle caps has also influenced the development of Helicap. Injection molding techniques have become more precise, enabling the creation of finer thread structures and better surface finishes. This precision has helped maintain compatibility with container neck finishes and sealing liners. As a result, the Helicap not only meets functional requirements but also contributes to the overall aesthetic and tactile quality of the package.

The evolution of Helicap can also be observed through its increasing role in customized packaging. Brands now seek to differentiate their products through closures that reflect identity and purpose. The versatility of polypropylene bottle caps has allowed for color customization, embossing, and tamper-evident features—all of which can be incorporated into the Helicap design. This level of flexibility strengthens brand recognition while maintaining high standards of packaging integrity.

Meanwhile, the market for screw cap alternatives continues to grow, especially in segments like flavored water, ready-to-drink teas, and health supplements. Here, the Helicap serves as a practical middle ground—offering the familiarity of a screw cap with added convenience. Its ability to reseal tightly after each use aligns with consumers’ expectations for portability and freshness.

In conclusion, the journey of the Helicap from a niche solution to a widely adopted closure style reflects broader trends in liquid packaging. With strong support from materials like polypropylene bottle caps and mechanical inspiration from the screw cap, the Helicap stands as an example of how functionality and user experience can drive innovation. As packaging continues to evolve, closures like Helicap will likely remain integral to the delivery of safe, accessible, and attractive liquid products across various industries.

English

English  русский

русский عربى

عربى